Indoor Grow Tent Setup Guide

Growing indoors is a great way to protect your plants from the conditions of the outdoors. But finding the right spot for your plants inside without a specific space set aside can be difficult.

With an indoor grow tent, not only can you grow your plants indoors in a secure space. A grow tent also gives you even more control over the environment your plants will grow in throughout their cycle.

Choosing an indoor grow tent

When choosing a grow tent, the main factors are the size and features. An average indoor grow tent will be 4′ x 4′ x 6.5′, which is a great compact size that still allows for optimal growth due to the height allowance.

To make everything easier, look for a grow tent with adjustable ports for vent fans/ducting, screened vent panels, and an adjustable power cord port. Growing in a tent will still require HVAC and lighting, and you don’t want to have to cut holes out yourself and risk tears that can lead to light leaks or temperature fluctuations.

The Lighthouse 2.0 Controlled Environment Tent is the perfect all in one tent, with all the above mentioned features. It also comes in a 4′ x 8′ x 6.5′ size for a wider area allowing more plants.

There are also smaller and even larger options for indoor grow tents. However it all depends on the size of your space, how many plants you want to grow and how much energy you’ll be able to provide through supplemental lighting and ventilation.

Once you have chosen your grow tent, it is time to get it set up.

Setting up your grow tent

Setting up an indoor grow tent is easier than setting up IKEA furniture, but it’s not always as easy as snapping a few corners and velcro together. Some grow tents might be made easy to assemble, while others have poles and joints that must be connected through the fabric of the tent to hold it up.

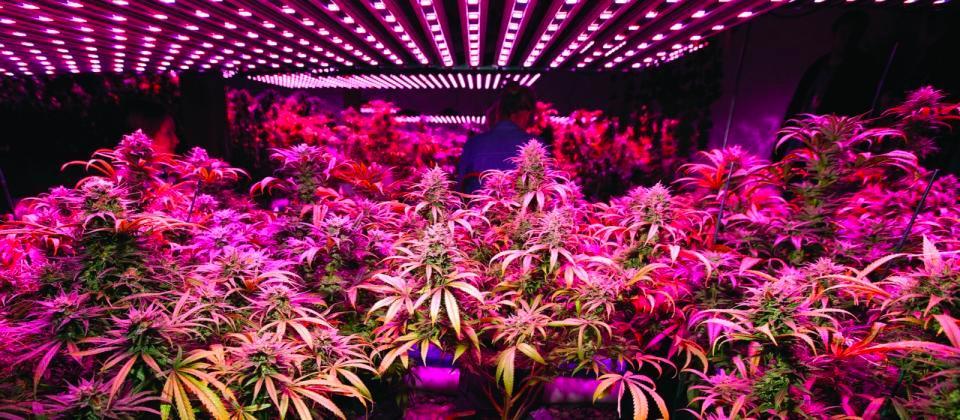

But we’re going to focus on setting up the tent once the frame has been built. This mainly involves setting up your lighting and ventilation using the vent ports and the support poles at the top of the tent.

In a smaller grow tent, air circulation can be taken care of easily with some clip on fans in the corners of the tent. However, additional ventilation like a carbon filter will need to be fed in through a vent port and supported if hanging in the tent.

This can include the carbon filter itself, plus an inline fan, tubing and the needed hardware. Ensuring that your carbon filter is supported and set up properly is going to make a big difference.

If your tent doesn’t have any built in ports to feed your tubing and wiring through, you may need to cut them yourself.

The lights you use will also depend on the size of your tent and how many plants you have. Check out our guide for finding the best grow light to make sure you don’t spend too much on a light that won’t cut it or damages your plants!

Aside from these two essentials, the customization you add to your grow tent is really up to you. The less plants you have, the more grow gear you can fit in with them like environmental controllers or a standing fan if you have larger plants.

Irrigation can also be useful in a grow tent for those who want to automate and maximize their efficiency. But in a smaller tent hand watering is likely easier and cheaper with just a few plants.

The biggest benefit of an indoor grow tent is that it gives you an environmentally controlled space wherever you want. No designing a grow room in your house or apartment required.

With ventilation, lighting, and water, your plants are ready to go in a secure, sealed environment.