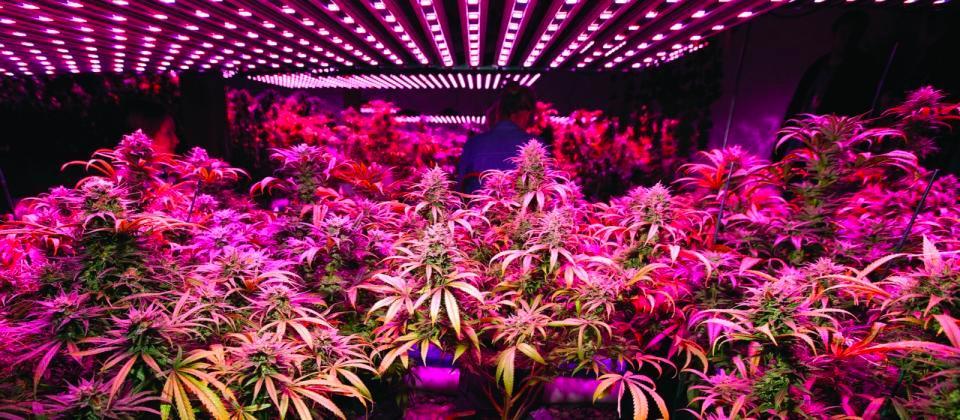

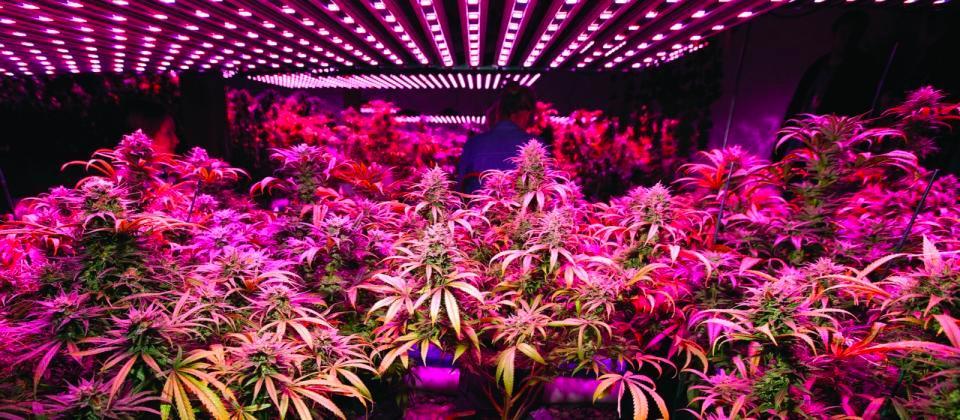

The History of Grow Lights and the Rise of LEDs

Lighting for indoor plant cultivation has evolved exponentially over the last twenty years.

A focus on creating the most cost-effective grow light has led to new technology and lighting applications that boost yields and produce way higher quality plants.

As long as electricity has existed, people have likely tried growing plants indoors. However most had no luck, as the power of lights back then was so minute compared to the power of the sun that growing indoors didn’t make any sense to the average farmer.

Jump ahead a couple hundred years and into the 20th century, and everything began changing. Cultivation techniques advanced, and so did technology.

The History of Grow Lights

The first patent for the next evolution of grow lights would be for the Metal Halide bulb, patented all the way back in 1912! But it wouldn’t be until the 1960s that this invention saw more practical, widespread use for cultivation. At this same time in 1962, LED lights would be invented. Remember this for later.

The metal halide bulb would act as the catalyst for the beginning of grow-light technology innovations, with High Pressure Sodium lights coming into the fray only four years after Metal Halide. With a higher wattage capability and stronger light spectrum, HPS lighting became the industry standard for decades.

However at this point, most growers were still just hanging bulbs from their ceilings. Also, the only bulbs available were 600 Watts or 1,000 Watts.

More innovation followed the introduction of HPS lights, like ballasts and reflective hoods to increase coverage and power and Ceramic Metal Halide bulbs in 1994, but in 2010 everything changed.

Gavita Lighting International invented the Double Ended Light Fixture in 2010, followed by the first Double Ended 750 Watt HPS Bulbs in 2013. This innovation completely revolutionized the way people could grow indoors, multiplying yields and quality exponentially.

Through all this innovation and technological advancement, LED Lights were slowly gaining steam in the background. Used primarily for home or commercial lighting, over the last decade LED lights slowly began breaking into the agricultural industry.

With more developments in LED tech over the last ten years, fixtures have been created that are now viable for commercial scale indoor cultivation. As innovators in the lighting industry, Gavita released their state of the art LED grow light in 2019 to revolutionize indoor cultivation yet again.

We are now entering what some would say is an infancy stage for LED grow lights. They are growing in popularity among home growers, but commercial and large scale growers are slower to see the appeal. Pair that with a high price point for quality LED lights and its easy to understand why they aren’t widespread quite yet.

Are LEDs Worth the Price?

While LED lights for cultivation are becoming more mainstream and effective, they definitely aren’t the cheapest option. CMH and HPS lighting have been the industry standard, which means more companies have produced economical options for growers at all levels.

Because LEDs have yet to become commonplace, the two options for growers are well-made lights that are proven to work from companies like Gavita for a higher price tag, or cheap, low quality LEDs typically produced in China. For the indoor grower with just a few plants, a cheaper light can get the job done, and it won’t break the bank when you need a new one after it inevitably breaks or malfunctions.

While a large scale grower can greatly benefit from using LED lights and they may even pay themselves off in time, a lot of cultivators can’t justify the high price point when HPS and CMH lights can do a great job for cheap in comparison. Over time the prices of LEDs will drop just like HPS did, and in a few years they will be just as common for growers, hopefully!